Length/Width/Height : 720mm(L)* 620mm(W) * 410mm(H)

Weight : 50KG(Gross Weight)

Shipping Method : DHL, UPS, FEDEX, EMS, TNT

Power : Max Power:3800W

Voltage : AC220V±0.1 50/60Hz

CF260 BGA rework station with three warm area:

BGA rework station, Brand new upgrade

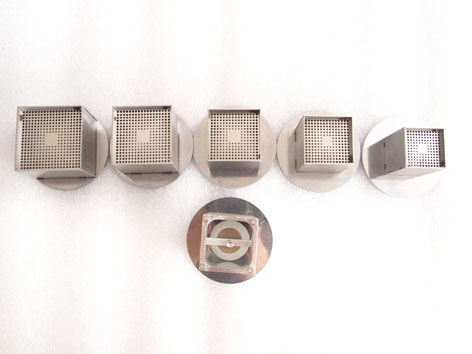

On July, 2012, upgraded tuyeres of CF 260 rework station. Standard configuration: two nozzles( 34mm, 45mm)

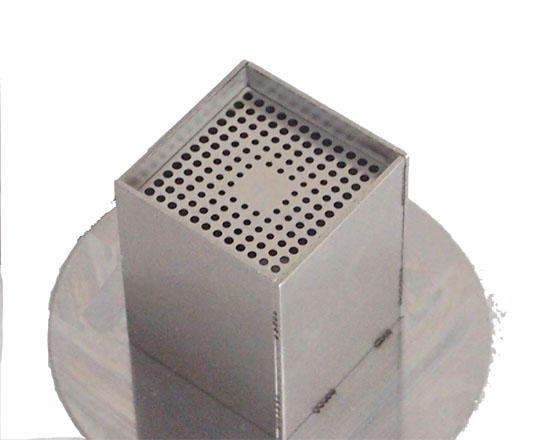

Stream guidance mesh by laser cutting, make air-out unifomlier.

CF260 BGA rework machine is a new economical rework machine innovated by Xinxuwei enterprise. Continue to use the professional instrument-control program and technology,and in order to cater to users' requirement for low cost, save some non-core design, then innovated this high cost-effective machine. Under insure being able to solder free lead repair perfectly, also save the biggest cost for users. - See more at:

CF260 BGA rework station with three warm area initiates the low price storm of BGA rework station!!!

CF260 Parameter: Upper heating power: 800W Below heating power: Bottom heating zone:800W, Preheating zone: 2200W Voltage: AC220V±0.1 50/60Hz Overall dimension: 720mm(L)*620mm(W)*410mm(H) Locate Mode: PCB holder can be adusted to X/Y direction at will , clip slot of V font , crocodile clip, hook of V font. Temperature Control: Closed-Cycle control with K Sensor, independent temperature control, precision - See more at:

PCB Size: W50*D50mm~ W440mm*D310mm Suitable Chip Size: 2*2mm-46*46mm Upper Nozzle Size: 28mm*28mm,35mm*35mm,38mm*38mm ,43mm*43mm ,46mm*46mm Bottom Nozzle Size: 34mm*34mm,45mm*45mm Manner of Working: Drive Machine Weight: 28KG - See more at:

CF260 characteristic:

1.The hot-air part adopts exported long-life heating coil, through special insulation heating treatment, heating uniformlier, long-life to use well.

2. The design of three warm areas support, can fine adjust to support height, avoid welding-area to sink.

3. Upper hot-air flow can be adjusted, to different BGA chips, choose different air-flow, temperature is more accurate, not easily explosive.

4. Upper and bottom hot-air control temperature separately, it can store 10 items with 16 stages temperature curve setting-up.

5. Overtemperature protection function,over the temperature, heating coil automatic power off.

6.Be applied to welding of lead soler and free lead soler flexibly, and meantime offer 10 groups of common referenced curve.

7. Machincal part adopts oxidation treatment, main machine box use thicken material, prevent shapeless at whole hog.

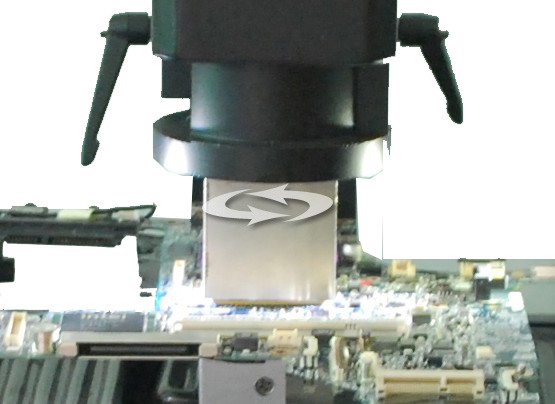

8. Upper heating part continue to use high-grade products' design of move by X/Y shaft, treating all kinds of shapeless chips easilier.

9. Three warm areas can be controlled separated, to achieve the function of soldering and dry.

10. Complete machine construction adopts the only design of dismounting easily, exchange electric parts simply and conveniently, warranty with fast speed, machine's rate of utilization reaches the highest.

Three warm areas' temperature-controlled instrument can achieve seperated temperature-control. Upper and bottom warm areas can store 10 items with 16 stages temperature curve setting-up. Closed-Cycle control with K Sensor, independent temperature control, precision:±1. Three warm areas can be controlled separated, to achieve the function of soldering and dry. Each warm area can achieve the function of keep during heating, strenghen manual intervention, increase success rate of welding. Standard configuration: 8 PCB holder,( 4 holders with hook, 4 holders with alligator clip), combine with fixture table, can position at any point on 360° plane, can clip all kinds of shapeless PCB board flexibly. Consumers can choose and match as personal need.

The design of inner notch can ensure to clip PCB and mounting hole of nobebook-board firmly, make PCB not easily to be shapeless when heating.

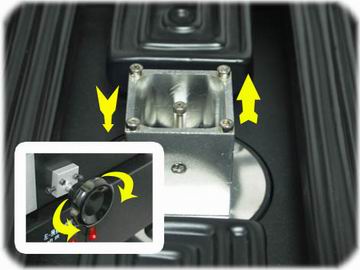

All the 5 single acmes of bottom nozzle can be fine adjusted the height to adapt different models' PCB. Two-sided PCB or PCB with elements, fine adjustment can realize the stress support to PCB uniformly. avoiding PCB to sink or shapeless and increasing the success rate of welding. Especially to the PCB with big size of elements on the back, the design of 5 single acmes can embody the prominent effect.

The bottom heating zone can be highly fine adjusted by screw handle on the sides of machine, turn the handle, bottom heating zone can be up and down, it all can be adjusted before clamping PCB or during welding. Based on our lots of welding experience, at curve's third and fourth heating zone, PCB can come into being heavy shapeless easily. Especially to the PCB non-roast, it will produce more stress after heating, it need to fine adjust handle during welding to support PCB more smoothly and ensure the success rate of welding.

Preheating zone can work separately to roast and stoving, besides, it also can be zone controlled and ensure heating square according to PCB size and installation site.

According to different requirements of different PCB heating position's size, upper heating zone can be moved at 360° as will. And the distance between chip and upper nozzle can be fine adjusted. According to the change of enviroment, it can be adjusted by manual intervention to increase success rate of welding.

Chinafix original-created and classical design of repeated air outlet with mixed air, makes air-out temperature uniformlier.

Imported thermal fuse, surface with Screenshot on video of thermal insulating treatment fuse's insulation test

5 upper nozzles: 28mm×28mm, 35mm×35mm,38mm×38mm, 43mm×43mm, 46mm×46mm

2 bottom nozzles:34mm×34mm , 45mm×45mm